Think about the process of making wine—what does this look like from the ERP level down to the plant-floor? A wine-maker has their specific batch of wine, which then the operation of making this batch of wine must have the perfect recipe to satisfy the wine-maker’s consumer base and then scheduled appropriately to optimize manufacturing time and execution. How is this even possible? With Conperio and ROB-EX Scheduler.

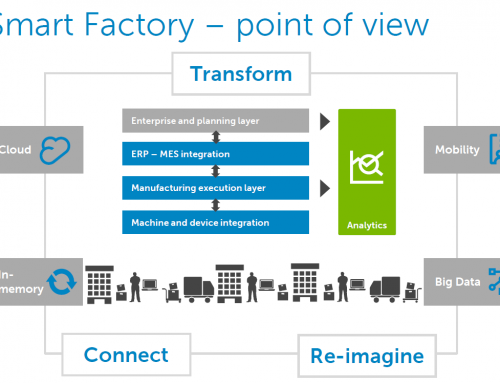

Conperio has mastered the art of Manufacturing Execution Systems (MES) solutions. MES guides, initiates, responds to, and reports on plant-floor activities as they occur—a proactive approach instead of reactive. At Conperio, we believe in creating technology that optimizes and connects equipment, people, processes, and systems. Machinery and people cost an organization money whether they are running or not—Conperio provides the opportunity to maximize utilization through solution-based technology tailored specifically for your wants, needs, and goals.

Conperio has partnered with GE as the only System Integrator for ROB-EX Scheduler in North America. ROB-EX Scheduler is a tool that can dynamically adjust to maintain full utilization at all times during plant-floor operations. With this partnership, the perfect marriage for manufacturing technology now exists. Conperio is able to tie in ROB-EX Scheduler’s capabilities with their MES solutions, integration work, and also custom application development in order to provide manufacturers operational excellence with ease of use.

Now when it comes to creating the perfect bottle of wine, Conperio and ROB-EX Scheduler have provided the solutions to plan, execute, and control the entire process from start to finish. From taste brainstorming, inputting the recipe, executing the operation, to the final product of wine—Conperio and ROB-EX Scheduler have transformed the way manufacturing technology and wine now co-exist for the better.