We’ve got you covered.

With Plex MES Automation and Orchestration, connect your Plex MES system to the plant edge to

control information flow and processes adding efficiency, saving cost, and eliminating manual errors.

Unleash operators from tedious data entry while improving accuracy and enabling them to focus

more on producing products and less on complex, manual processes.

Extend your capabilities

We’d all like to have an infinite number of people who are infinitely fast at entering data, but

that is not realistic. Plex MES Automation and Orchestration works with Plex MES to simulate an

infinite workforce, automating data capture and entry in real-time and feeding the digital system

of record. Additionally, Plex MES Automation and Orchestration adds helpful visualizations to

better understand your processes at the most granular level.

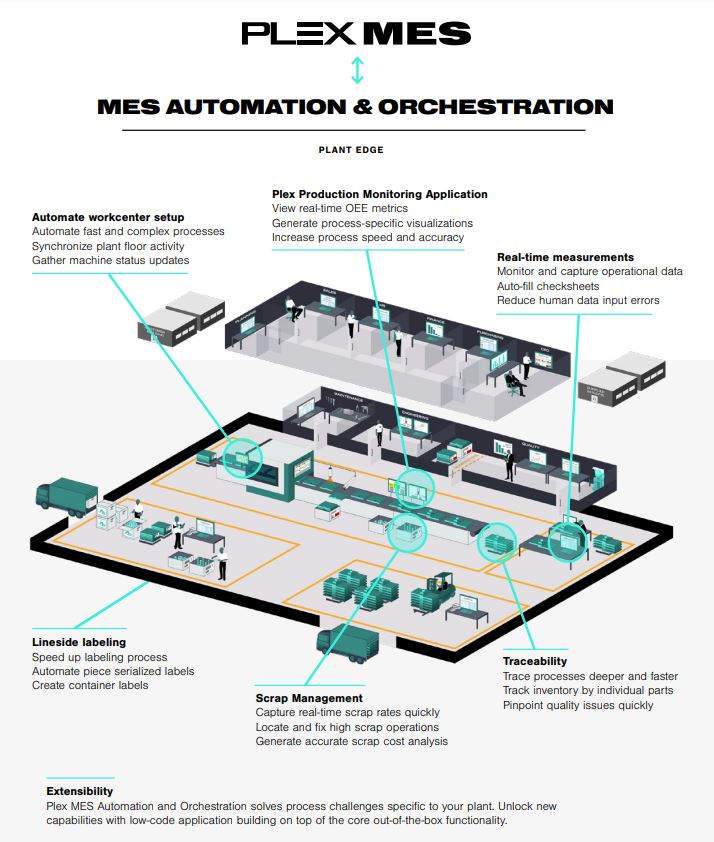

How does it work?

Plex MES Automation & Orchestration interacts with your plant floor machines and systems

using PTC Kepware software or other plant floor drivers and protocols to provide real-time,

actionable information. Automated data entry improves accuracy and enables your operators to

focus on what matters. Connecting to the plant edge allows for effective control of information

flow and processes for added efficiency, cost savings, and manual error reduction.

Automate data capture

Manually inputting data is tedious, time consuming, can lead to human error, and—in some

cases—is not possible at all. Plex MES Automation and Orchestration removes the risks

associated with manual data management. Let’s say you need to weigh raw material before it

goes into production. Plex MES Automation and Orchestration can take weigh scale data from

your production line and automatically populate checksheets without ever having to input the

data by hand. If you need to record torques and angles of bolts, you can set up your tools to

capture the data and Plex MES Automation and Orchestration can manage that data effectively

based on requirements. As you can imagine, this is much faster and more accurate than

assigning an employee to that station for the sole purpose of inputting data.

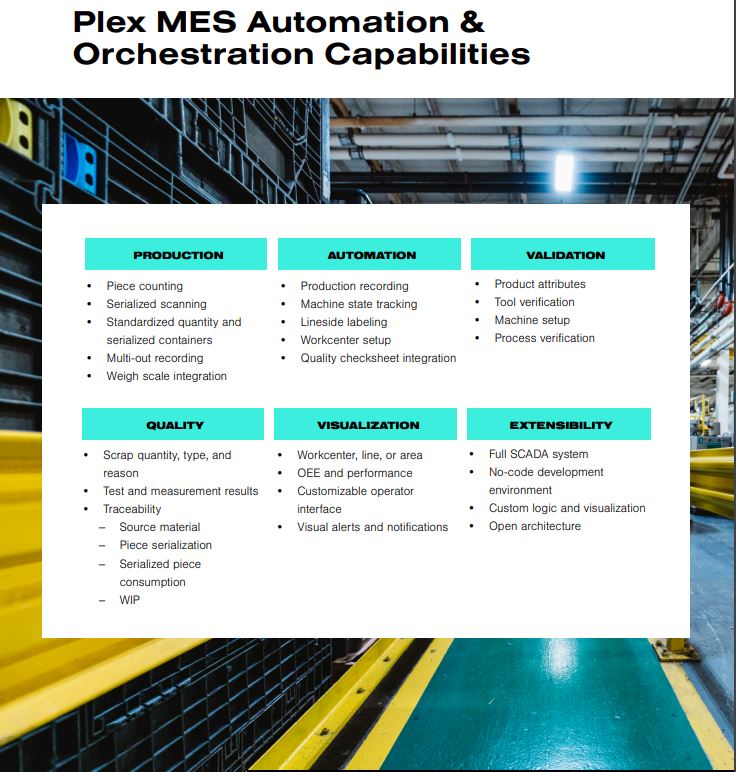

Toolkit to enhance your Plex MES

Plex MES Automation and Orchestration can solve unique problems that are specific to your

plant using low-code—drag and drop—application building on top of the core out-of-the-box

functionality to create complex process flows and unlock new possibilities.