Plan. Execute. Control. Complete.

What is MES?

-

MES stands for Manufacturing Execution Systems

-

Sometimes referred to as MOM or Manufacturing Operations Management

-

Shop Floor Production System

-

And many others

-

-

MES enables optimization of production activities from order launch to finished goods

-

MES guides, initiates, responds to and reports on plant activities as they occur

-

This rapid response to changing conditions coupled with a focus on reducing non-value added activities drives effective plant operations and processes

-

MES improves the return on operational assets as well as on-time delivery, inventory turns, gross margin, and cash flow performance

-

MES provides mission critical information about production activities across the enterprise and supply chain via bi-directional communications

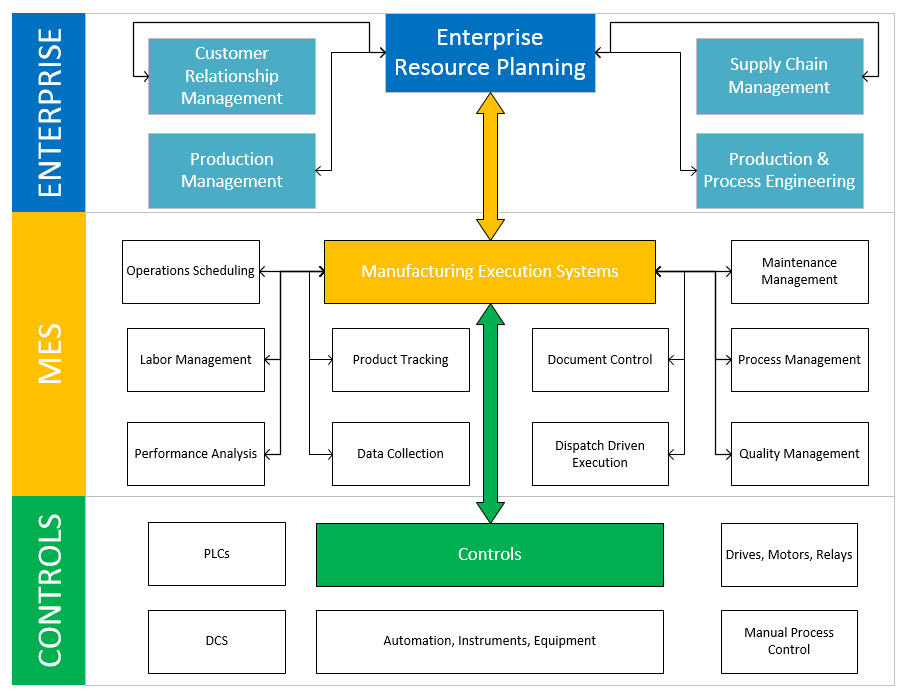

What are MES Applications?

(and where does it fit in my plant)

ERP “why” – MES “how to”

-

ERP primarily supports strategic decisions

-

MES supports operational decisions

-

Those who know “how to” make things, always works for those who know “why”

-

But those who know “why,” must rely on people who know “how to” to turn their decisions into reality

-

ERP is not designed to Reach Shop or Plant Floor

-

No machine that produces a piece per cycle probably will ever communicate to the ERP that it completed the cycle

-

Shop Floor MES production systems and ERP systems operate on different interpretations of “real time.”

-

ERP is focused on the strategic management of the business

-

MES is associated with the punctual execution of the process

-

ERP and MES systems must communicate and act as a seamless whole to allow the manufacturing industry to meet dynamic needs coming from:

-

Customers

-

Regulators

-

Suppliers

-

And even internal staff

-

MES Benefits

-

Increases operational excellence

-

Improves asset utilization and management of assets

-

Reduces manufacturing cycle times

-

Reduces work in process

-

Reduces paperwork between shifts

-

Reduces lead times

-

Improves product quality

-

Eliminates lost paperwork

-

Empowers plant operations staff

-

MES functionality can be implemented between plants with minor “tweaks” for each specific plant site thus lowering costs across the board

Data Flow – ERP and MES

ERP

Forecasting

Costing

High Level Production Planning

Product Definition

Process Definition

Human Resources

Inventory Management

Purchasing

Distribution

MES

Resource Allocation/Status

Operations Scheduling

Production Dispatching

Document Control

Data Collection

Labor Management

WIP Status and Traceability

Quality Management

Performance Analysis

Product Tracking

Maintenance

Process Instructions

Visual Work Instructions